- Time: 2024-04-22 Views: 54

Type T and L types of electric ball valves are mainly different in the internal structure, functions and applications.

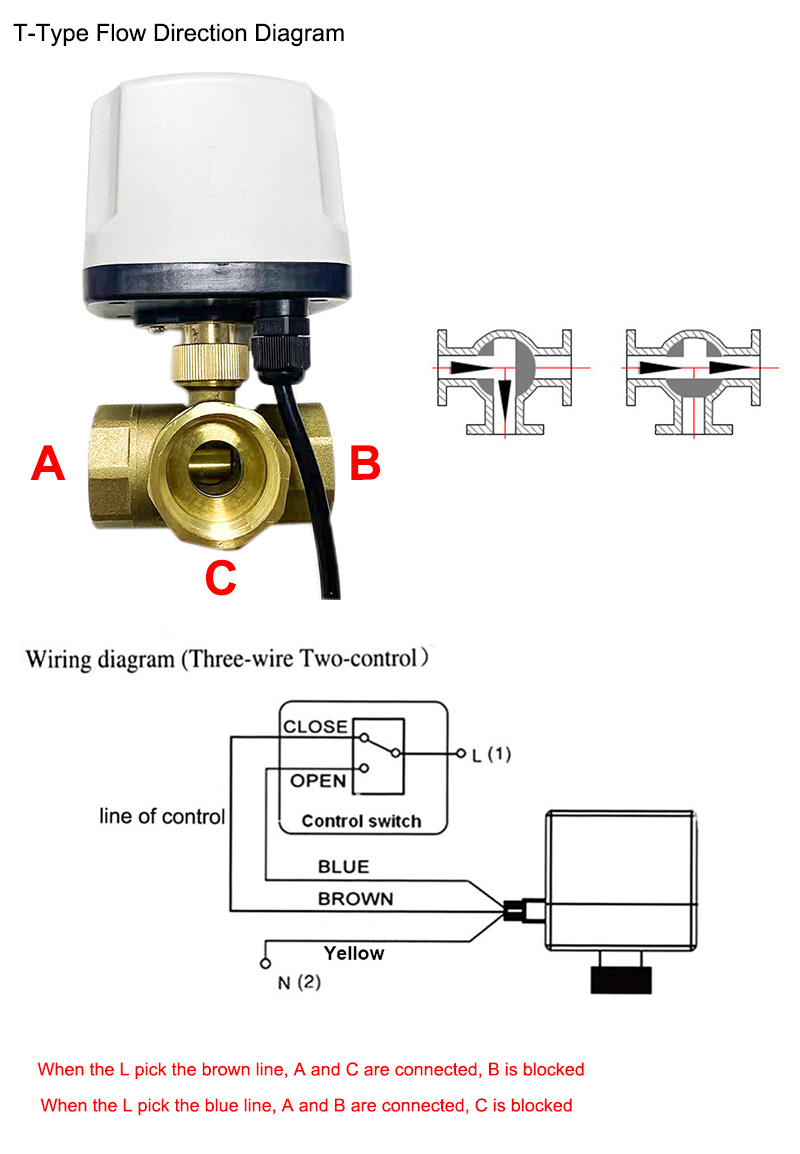

Internal structure: The structure of the T -type electric three -way ball valve enables them to connect the three orthodontic pipelines and cut off the third channel to play a role in diverting. The L -shaped electric three -link ball valve can only connect two orthogonal pipelines, and cannot maintain the interconnection of the third pipeline at the same time, and can only play a role of allocation.

Function: The T -type three -link ball valve is more flexible in fluid control. It can not only connect the three pipelines, but also control any two pipelines. The L -type three -tech ball valve is mainly used to control the two pipelines. The operation is relatively simple. There are only two valve positions. There are positioning, which can be 90 degrees.

Application: Due to the large number of channels and many valve positions in the T -type three -way ball valve, it is usually used in occasions without specific requirements or more flexibility. The L -type three -way ball valves are more suitable for those who do not need 3 -pass allocation and switching, or need more concise operations.

In summary, the T -type and L types of the electric ball valve have their own characteristics in structure, functions and applications. Which type of selection mainly depends on the specific fluid control requirements and operating requirements. In practical applications, the appropriate type should be selected according to the specific working environment, fluid nature and control requirements.